Total Suspended Solids

Total Suspended Solids (TSS) apply to the dry weight of the material that is removed from a measured volume of water sample by filtration with a standard filter. The test is basically empirical and is not subject to the usual criteria of accuracy.

To achieve reproducibility and comparability of results requires close attention to procedural details, especially filter characteristics and time and temperature of drying.

Apparatus

- Filter holder

- Desiccators are provided with a desiccant containing a color indicator for moisture

concentration - Analytical balance capable of weighing to 0.001 g

- Glass-fiber filter disc, Whatman GF/C or equivalent

- Suction flask apparatus, 500 mL capacity

- Vacuum pump

- Crucible

- Drying oven

- Buchner funnels

Procedure

A. Pre-treatment of filter disc and crucible

- Place a filter disc on the filter holder. Assemble filter holder in suction flask apparatus,

connect to a vacuum source and apply the vacuum. - Wash the filter disc with 3 successive 20-mL portions of DI water. Apply the vacuum

for 2-3 minutes after the water has passed through the filter. Discard the filtrate. - Remove the filter paper from the membrane filter funnel or the Buchner funnel and place it

on a supporting surface in the drying oven.

- Place the crucible (s) in the drying oven. The oven should be maintained at 105 oC and the drying should be continued for at least 1 hour.

- Cool the filter (s) and crucible (s) in desiccators and weigh them on an analytical balance.

- Repeat the drying, desiccating, and weighing cycle until the weight loss between two successive series operations is less than 0.5 mg.

- Store filter (s) and crucible (s) in desiccators until required.

B. Determination

- Remove the filter disc and crucible from the desiccators, and weigh (Wtf+c).

- Place the filter in the filter holder and assemble the filter holder in the suction flask apparatus. Connect to the vacuum source and apply the vacuum.

- Wet the filter with a few drops of DI water to seat the filter.

- Shake the sample vigorously and measure out 100 mL in a 100-mL graduated cylinder or volume flask. Pour this portion of the sample into the filter funnel (be careful not to disturb the placing of the filter disc).

- Rinse out the measuring flask or cylinder with a small quantity of DI water. If the sample is very low in suspended material, a large sample may be used.

- When filtration is complete, carefully remove the filter disc from the filter holder with tweezers (or remove the crucible from its supporting socket with a pair of tongs), and place it in the drying oven.

- Dry for at least 1 hour at 105 oC. Cool in desiccators, and weigh (Wtf+c+s).

- Repeat the drying, desiccating, and weighing cycle until the weight loss between 2 successive weighings is less than 0.5 mg.

- Record the final weight obtained.

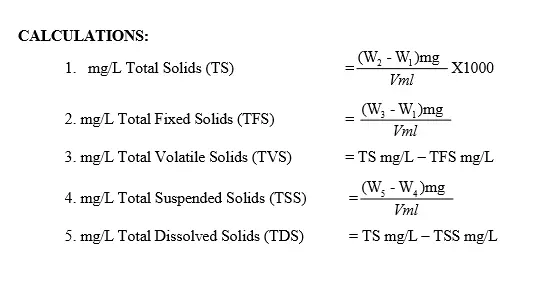

Calculation

Technical Remarks

- It is necessary to report the specifications followed, e.g., TSS at …oC, type of filter, and pore size or number.

- Non-homogeneous particulates such as leaves, sticks, and lumps of fecal matter should be excluded from the sample. Too much residue on the filter will retain water and may require prolonged drying.

- Long-term sample preservation is not practical; analysis should therefore begin as soon as possible. Transportation and short-term storage of samples normally do not affect the results of the test.

- Volatile material in a sample can distort results.